Date:2024-05-28 14:23:35

Implantable bioelectronics can treat various medical conditions by interfacing with biological tissues. Traditional rigid electronics often damage tissues and fail due to mechanical mismatch. Researchers are exploring soft, flexible bioelectronics to address this issue, with hydrogels emerging as a promising material due to their tissue-like properties.

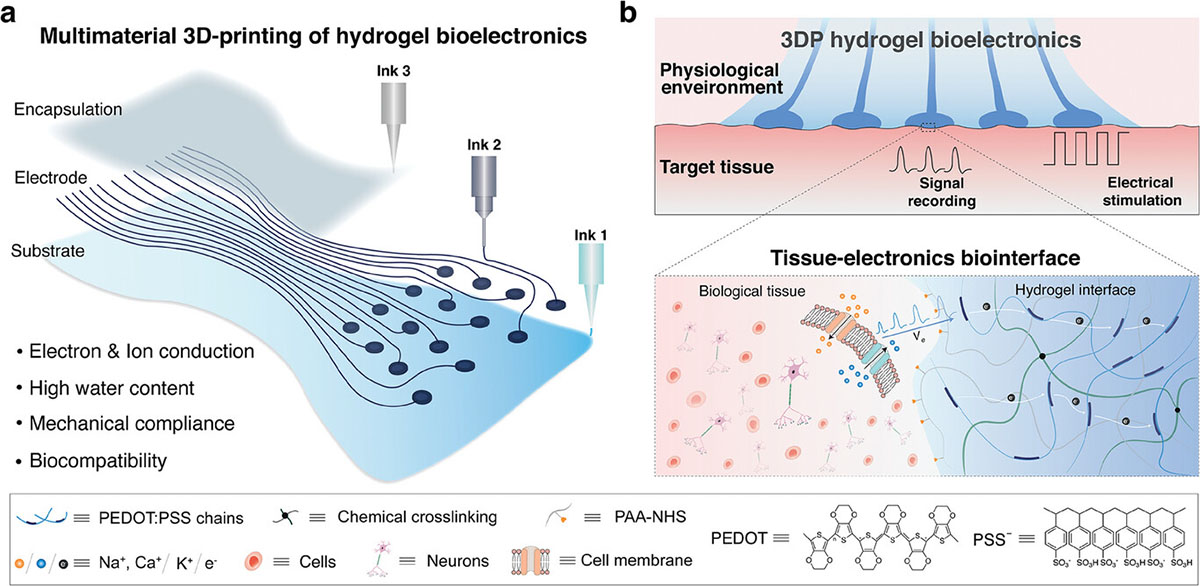

Recent work by Chinese researchers has developed 3D printable conducting polymer hydrogels, significantly advancing the field. These hydrogels combine the desirable properties of hydrogels with the electrical conductivity of conducting polymers like PEDOT. This development involves formulating inks for direct ink writing (DIW) 3D printing, creating a substrate, electrode, and encapsulation layers.

3D Printing Conducting Polymer Hydrogels for Bioelectronics

Infographic showing the hydrogel printing process. (Image Credit: Southern University of Science and Technology)

Key to their success is the use of polyvinyl alcohol (PVA), chitosan (CTS), and a synthetic copolymer (PAA-NHS) to achieve a balance of physical and chemical cross-linking mechanisms. PEDOT also serves as a rheological modifier, ensuring the ink flows smoothly during extrusion and solidifies accurately post-printing. This allows the fabrication of complex 3D structures with high fidelity and long-term stability.

A significant feature of these hydrogels is their ability to adhere strongly to biological tissues, facilitated by a dry cross-linking mechanism. This adhesion is crucial for maintaining a stable interface during dynamic tissue movements.

The researchers have demonstrated the potential of these hydrogels in electrophysiological studies on rat hearts. The bioelectronics conformed to the beating heart and enabled precise mapping of electrophysiological signals, detecting abnormalities and delivering electrical stimulation to restore normal heart rhythm.

This technology could extend to various implantable devices, such as neural interfaces and gastric stimulators, improving their performance and biocompatibility. However, challenges such as long-term biocompatibility, scalability, and regulatory approval remain to be addressed.