Date:2024-06-04 10:51:42

Assembly of multimaterials into complex 3D structures presents challenges in traditional manufacturing. However, a recent study has introduced a Freeform Multimaterial Assembly Process (FMAP) that integrates various techniques to seamlessly assemble both structural and functional materials into multifunctional objects.

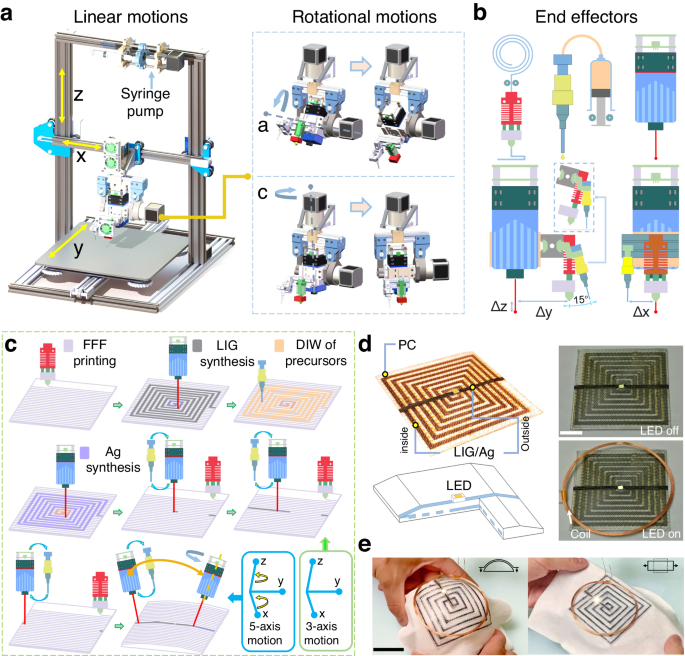

This process combines Freeform Laser Induction (FLI), Direct Ink Writing (DIW), and Fused Filament Fabrication (FFF) to enable the creation of intricate 3D objects with diverse functionalities.

Researchers Advance Multimaterial Assembly in 3D Printing

Schematic of FMAP platform and workflow of fabricating 3D devices by assembling structural and functional materials using FMAP. (Image Credit: University of Missouri)

The FMAP method allows for the precise placement of functional materials within 3D structures, addressing limitations in current multimaterial fabrication techniques. By leveraging FLI, which enables direct fabrication of 3D electronics on freeform surfaces, alongside DIW and FFF, the process achieves versatile assembly of materials with reduced waste and increased customization.

Key advancements include:

Streamlined Assembly: FMAP eliminates the need for multiple processing steps in different apparatuses, simplifying the manufacturing process.

Versatility: With FLI, functional materials can be patterned in any predetermined location within the 3D structure, enhancing design flexibility.

Material Utilization: The method reduces precursor waste streams by directly processing different functional materials, improving material efficiency.

Functional Diversity: The resulting 3D objects exhibit diverse functionalities, including LEDs, strain sensors, UV sensors, electromagnets, and microfluidic reactors, demonstrating the wide-ranging applications of FMAP.

Experimental results have confirmed the effectiveness of FMAP in fabricating complex 3D structures with integrated functional components. Tensile testing and material property characterization reveal well-maintained mechanical properties and superior electrical conductivity of the fabricated materials.

Overall, FMAP represents a significant advancement in multimaterial assembly, offering a promising pathway for the development of integrated, multifunctional 3D objects across various industries, including electronics, robotics, and microfluidics.