Date:2025-09-22 10:37:14

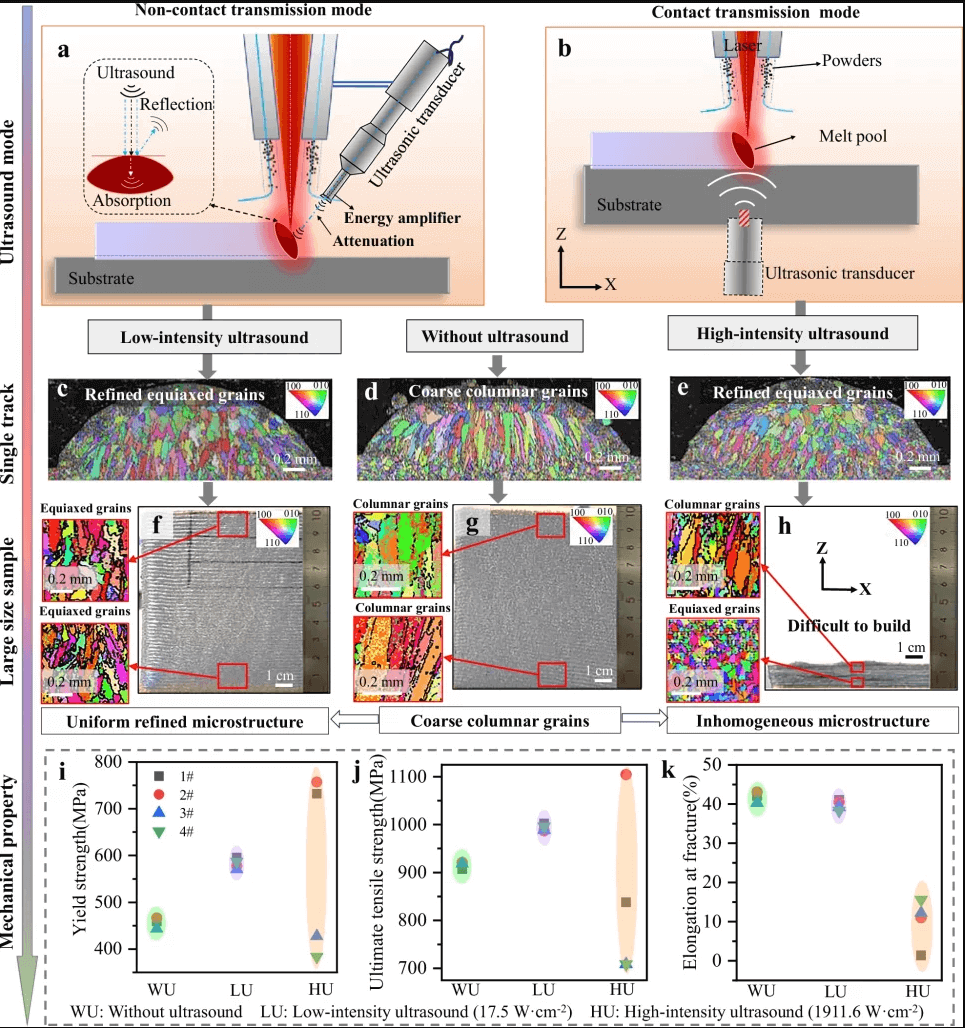

Northwestern Polytechnical University in Xi’an, working with Wuhan University of Science and Technology, the National University of Singapore, and Trinity College Dublin, has demonstrated a non-contact ultrasound method for laser additive manufacturing. Published in Nature Communications, the work shows that transmitting ultrasound below 20 W·cm² through a gas medium refines grains and enhances mechanical performance without cavitation. In tests with Inconel 718, yield stress increased from 456 to 582 MPa (+27.6%) and tensile strength rose from 915 to 994 MPa (+8.6%), while ductility remained nearly constant at about 40%. Similar results were achieved with stainless steel 316L, indicating the approach is broadly applicable.

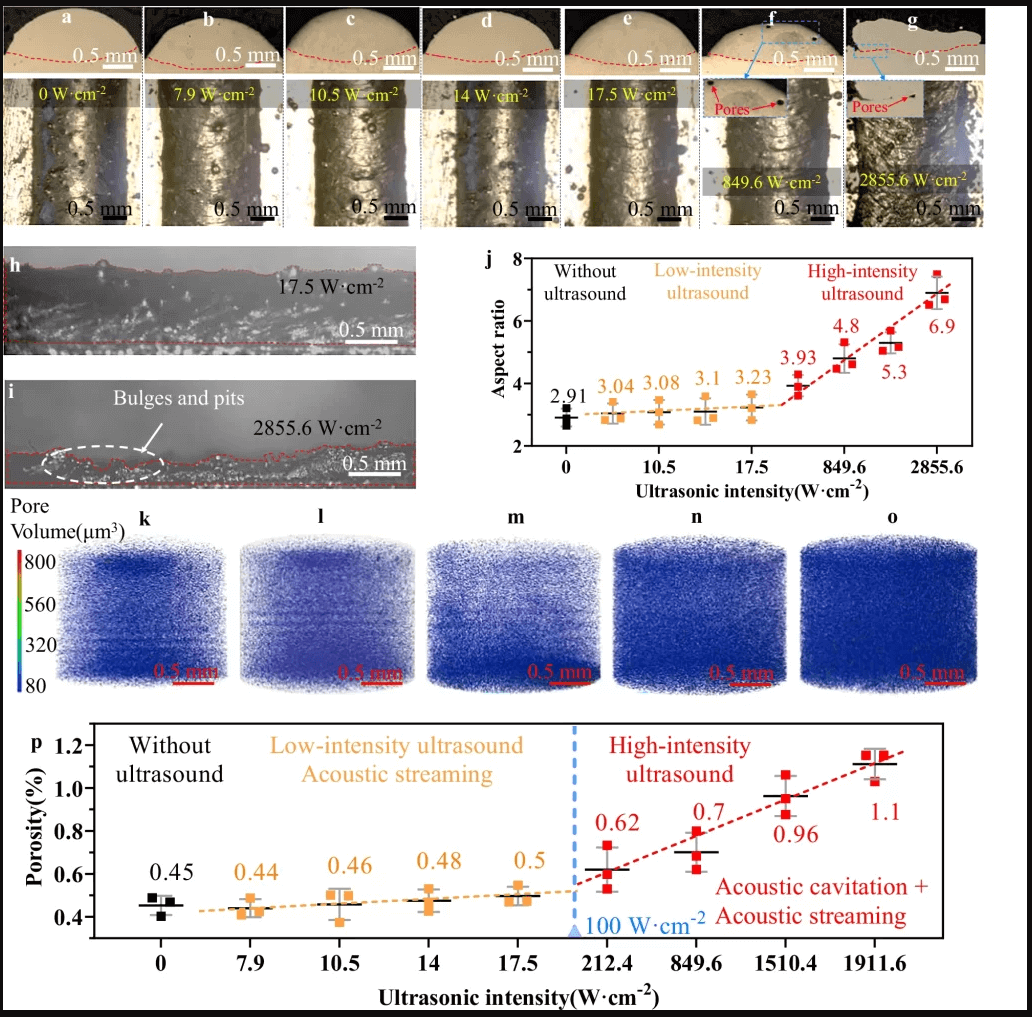

Laser additive manufacturing usually produces columnar grains due to steep thermal gradients in the melt pool, which limit mechanical properties. Conventional ultrasound-assisted processing uses direct contact between a transducer and substrate, transmitting ultrasound intensities above 200 W·cm². While this high-intensity method can refine grains, it introduces instability. Computed tomography revealed porosity increasing from 212.4 to 1911.6 W·cm², accompanied by bulges and pits, which restricted builds to heights below 15 mm. By contrast, the non-contact mode transmitted ultrasound through the carrier gas at intensities below 20 W·cm², avoiding cavitation. Samples up to 100 mm tall reached near-full density and maintained grain refinement throughout deposition.

The schematic of low-intensity ultrasound by non-contact-transmission mode. In this mode, the ultrasonic transducer with an energy amplifier is fixed with the powder feeder. Image via Nature Communications.

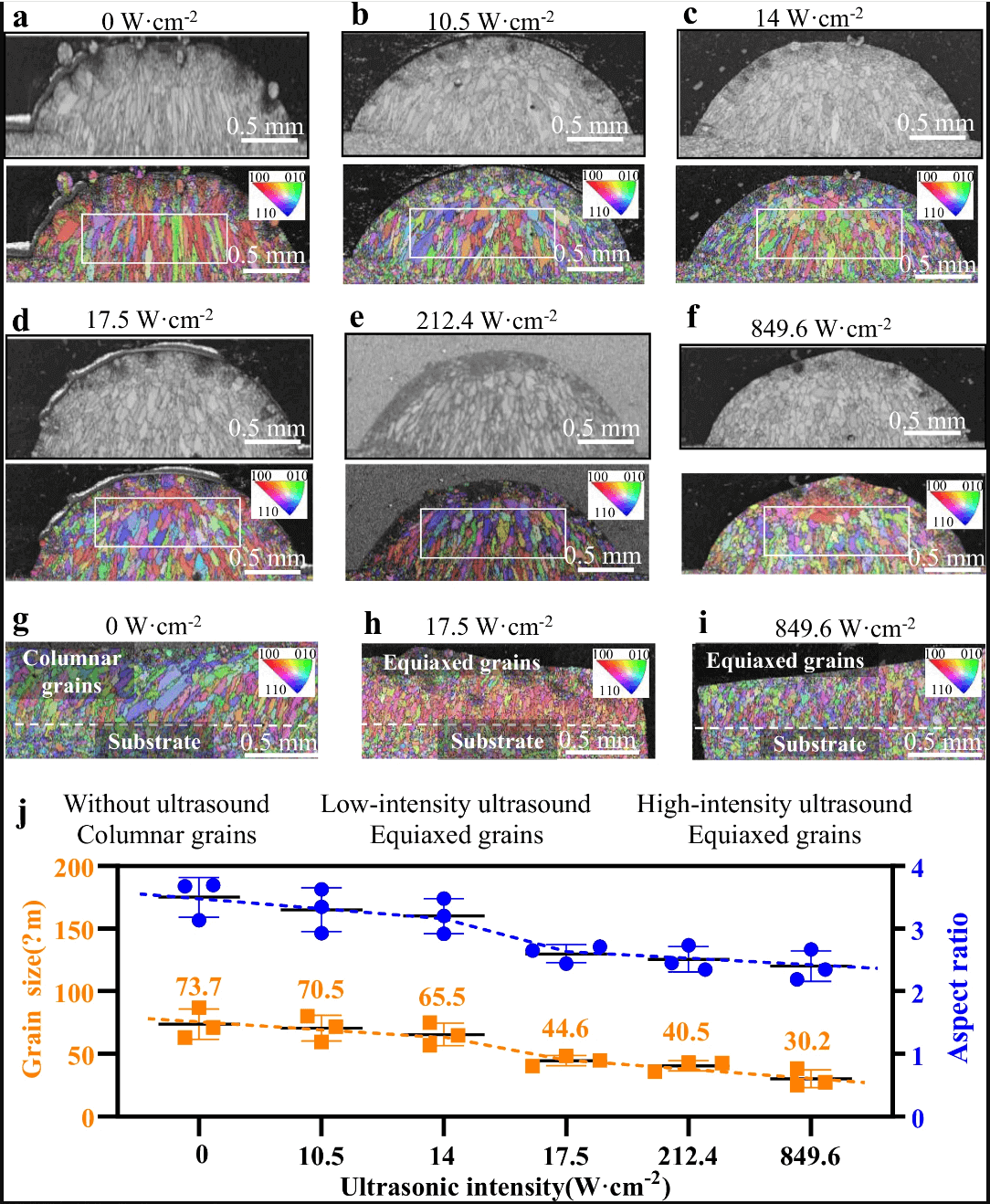

Northwestern Polytechnical University’s team mounted the transducer to the powder nozzle, keeping a fixed distance from the melt pool as layers were deposited. This configuration ensured stable ultrasound delivery across heights, producing uniform equiaxed structures. Grain size analysis showed an average of 73.7 μm without ultrasound, reduced to 44.6 μm with non-contact ultrasound at 17.5 W·cm². Contact ultrasound achieved finer grains of 30.2 μm at 849.6 W·cm², but porosity and surface defects increased sharply. Grain transition points also differed: equiaxed grains appeared above 1.0 mm in non-contact samples compared to 0.6 mm in high-intensity builds. Contact-transmission effects weakened above 10 mm, where grains reverted to columnar structures, while the nozzle-mounted method preserved refinement throughout 100 mm blocks.

In-situ monitoring and multiphysics simulations clarified the physical mechanism. Low-intensity ultrasound combined with Marangoni-driven flow to generate a high-frequency shaking motion in the melt pool. This motion subjected dendrite arms to cyclic stresses exceeding the material’s 37.3 MPa yield strength, causing fatigue fracture and fragmentation. Calculations showed dendrite stress rising from 30.9 MPa without ultrasound to 71.3 MPa under non-contact ultrasound. Unlike cavitation, which produces violent bubble collapse and shock waves, acoustic streaming maintained a stable melt pool surface. Porosity under low-intensity conditions rose only marginally, from 7.9 to 17.5 W·cm², confirming that defects were avoided while refinement occurred.

Effect of ultrasound on fusion defects of Inconel 718. Image via Nature Communications.

Earlier studies in welding, cladding, and casting concluded that cavitation was the primary cause of grain refinement, with acoustic streaming considered negligible. More recent synchrotron X-ray imaging revealed streaming flows in laser AM but still attributed refinement to cavitation, since intensities in those tests exceeded the threshold. The present study demonstrates refined equiaxed grains under conditions where cavitation cannot occur, proving that streaming alone can drive refinement. This result resolves the long-standing uncertainty over streaming’s role and addresses the scalability problem in ultrasound-assisted AM.

Mechanical property tests highlighted the difference in reproducibility. Non-contact samples showed consistent yield strengths clustered near 582 MPa and ultimate tensile strengths around 994 MPa. Contact ultrasound builds varied widely: yield strength ranged from 427 to 757 MPa, and tensile strength from 890 to 1070 MPa, due to porosity and non-uniform microstructures. The authors report that the non-contact technique achieved repeatable performance in both alloys tested, contrasting sharply with the variability of high-intensity ultrasound.

Effect of ultrasound on grain structure of Inconel 718 single tracks. Image via Nature Communications.

By showing that cavitation is not required to refine grains, this work redefines assumptions in ultrasound-assisted metallurgy. Non-contact ultrasound below 20 W·cm² produced refined grains, reproducible strength, and defect-free surfaces in alloys widely used in aerospace and energy applications. The researchers note that the approach can also be adapted for laser cladding and welding, where melt pool stability is critical. The findings establish acoustic streaming as a viable mechanism for microstructural control and point to reproducible strategies for manufacturing large, complex metal components.