Date:2024-06-04 10:49:21

Researchers from Shandong University have proposed a new alloy design approach for NiTiNb shape memory alloys (SMAs). The method employs Laser Beam Powder Bed Fusion (PBF-LB), in-situ alloying and post-heat treatment. This study, published in the International Journal of Extreme Manufacturing, aims to address challenges in fabricating NiTiNb ternary alloy structures.

Researchers Develop Shape Memory Alloys with Powder Bed Fusion

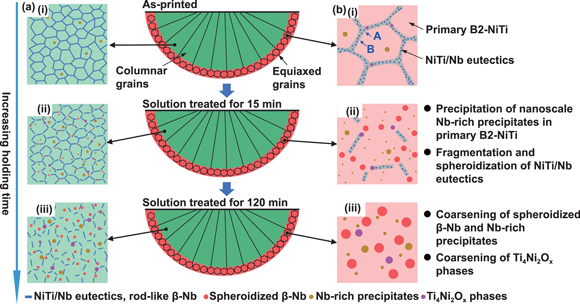

Infographic showing the microstructure evolution of the 3D printed alloy before and after the treatment. (Image Credit: Shandong University)

The (NiTi)91Nb9 alloy was produced using pre-alloyed NiTi and elemental Nb powders. The research investigated the effect of solution treatment on microstructure, phase transformation behavior, and mechanical/functional performance. NiTi-based SMAs are of interest for biomedical, aerospace, and automotive applications due to their shape memory effect and superelasticity. Adding Nb enhances thermal hysteresis and mechanical properties, beneficial for sealing and coupling applications.

PBF-LB can produce complex NiTi parts and serves as an effective in-situ alloying method, offering flexibility in compositional and microstructural design and reduced lead times. Post-heat treatment enhances compositional uniformity and stabilizes service performance. Previous studies indicate improved mechanical performance in LPBF-fabricated binary NiTi alloys through modulating secondary phase distribution.

This study found that heat treatment significantly improves the mechanical/functional performance of (NiTi)91Nb9 alloys, resulting in alloys with excellent tensile properties and wide hysteresis. The findings provide insights into developing high-performance NiTi-based SMAs using PBF-LB in-situ alloying and post-heat treatment.