Date:2024-06-17 16:30:35

A team of undergraduate students from the University of Utah has won the ASME/K-16 and IEEE/EPS Student Design Challenge for the second consecutive year. The competition tasked students with designing an additively manufactured heat sink to operate under forced air conditions with stainless steel and a low power input of 3W.

Utah Students Win Heat Sink Challenge

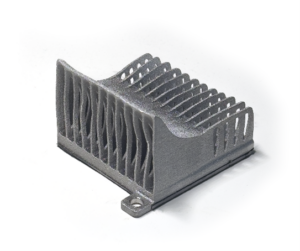

3D printed Venturi Plate heatsink. (Image Credit: University of Utah)

Team members Zane Frey, Eric Montenegro, Nathan Brown, Joshua Brodbeck, and Oliver Proctor, advised by Dr. Sameer Rao, conducted a parametric study on conventional plate fin heat sinks. They experimented with variables such as plate number, thickness, and height to find an optimal balance of thermal performance and mass.

The team eventually settled on a venturi plate heat sink design. By leveraging a venturi tube geometry, they enhanced airflow channeling and convection heat transfer near the base plate, overcoming stainless steel’s low thermal conductivity. Their design was 3D printed using GE’s binder jet technology and successfully tested.

The team presented their winning heat sink at ITherm 2024 and expressed gratitude for the support from Dr. Rao and the U’s 3D Metal Printing Lab. They look forward to future competitions as part of the senior design capstone program.

The University of Utah team continues to demonstrate excellence in heat sink design, securing victories in 2020, 2022, and 2023.