Date:2024-07-02 14:49:15

Researchers in Japan have developed a PEEK ink that can be printed with DLP technology. Polyetheretherketone (PEEK) is a high-performance plastic known for its mechanical strength, thermal resistance, and chemical stability. Traditional methods to fabricate complex PEEK structures are limited by poor resolution, surface quality, and interlayer bonding.

High-Performance PEEK 3D Printing with DLP Technology

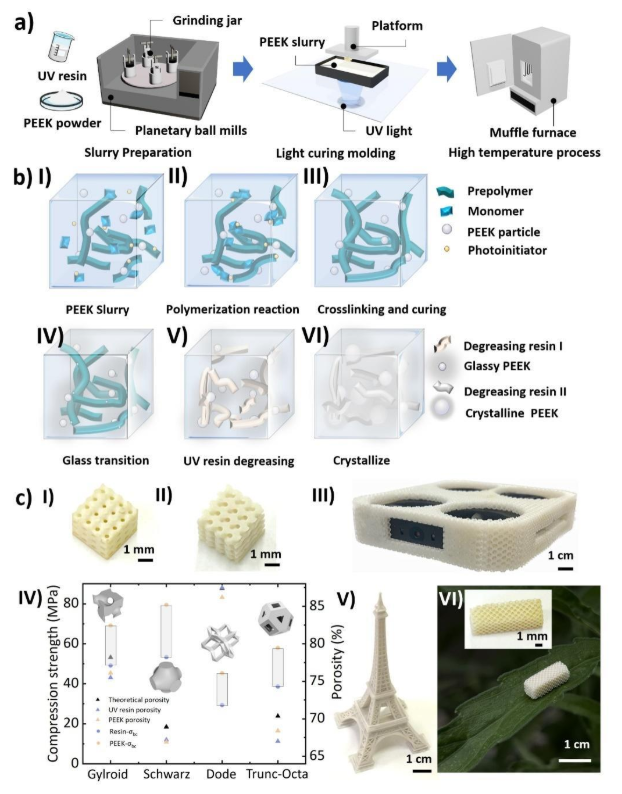

Infographic showing the mixing, printing and sintering of the PEEK ink. (Image Credit: Zhang et. al)

This method involves creating high-solid-content PEEK ink and using DLP to produce high-precision green bodies, followed by one-step sintering to enhance crystallinity. PEEK micron powders mixed with photosensitive resins form the ink, which is cured using 405 nm UV light. Post-printing, the structures are sintered in a nitrogen atmosphere to achieve desired mechanical and thermal properties.

The printed PEEK structures exhibit improved thermal stability, heat resistance, mechanical strength, and corrosion resistance. Tests included exposure to hydrochloric acid, sodium hydroxide, acetone, and chloroform. The new process enables the creation of complex architectures with higher accuracy and better surface quality compared to traditional methods such as FDM.

This project leverages the superior properties of PEEK, allowing for flexible, efficient, and high-resolution applications in fields like aerospace, automotive, electronics, and biomedical industries. The research broadens PEEK’s application prospects, particularly where high structural complexity and resolution are essential.