Date:2024-07-08 14:27:09

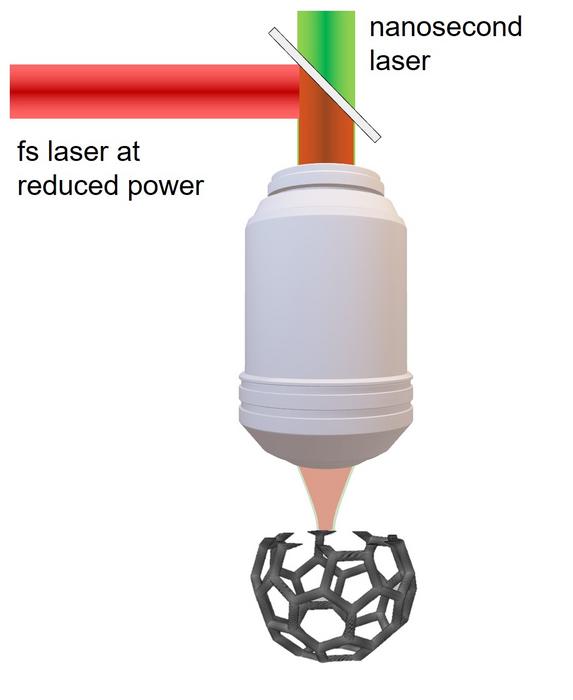

Researchers from Purdue University have developed a two-photon polymerization technique using two lasers to create complex high-resolution structures. This method combines a low-cost nanosecond laser with a reduced-power femtosecond laser, making the process more affordable.

Traditionally, two-photon polymerization relies on expensive femtosecond lasers, limiting its use in manufacturing. By using a visible light laser along with an infrared femtosecond laser, the power requirement for the latter is significantly reduced. This approach increases printing throughput and decreases the cost of individual parts.

Researchers Unveil Cost-Effective High-Resolution 3D Printing Process

Diagram showing the dual-laser approach. (Image Credit: Anwarul Akash, Purdue University)

Published in Optics Express, the study demonstrates a 50% reduction in femtosecond laser power needed. This dual-laser method can be applied in existing femtosecond laser systems, making it accessible for various applications like 3D electronics, micro-robots, and tissue engineering scaffolds.

Specifically the technique involves a 532 nm nanosecond laser, and an 800-nm femtosecond laser, balanced to optimize printing while managing inhibition effects. A new mathematical model was developed to understand the photochemical processes and compute the combined effects of single and two-photon excitations.

Experiments showed up to an 80% reduction in femtosecond laser power for 2D structures and around 50% for 3D structures, including woodpiles, buckyballs, and chiral structures.

This method could significantly influence manufacturing technologies in consumer electronics and healthcare, with ongoing research aimed at further improving speed and reducing costs.